LASIT has recently realized a robotic system for laser marking engine blocks providing a 6-axis ABB anthropomorphic robot as the core of the operating cycle integrated in the cabinet.

Robotic laser marking cabinet realized by LASIT

Marking and engraving are among the most employed laser applications in the industrial domain. As far as laser technology is concerned, since 1990 LASIT has been one of the most influential company, with over 2000 customers around the world and hundreds of models developed from simple laser engravers for small quantities to fully automatic complex systems made for customer needs. One of these advanced models is, as a matter of fact, the robotic laser marking system for engine blocks, that the Italian company has recently designed in partnership with ABB Robotica, society that has furnished the 6-axis ABB anthropomorphic robot integrated in the cabinet.

6-axis robot marking

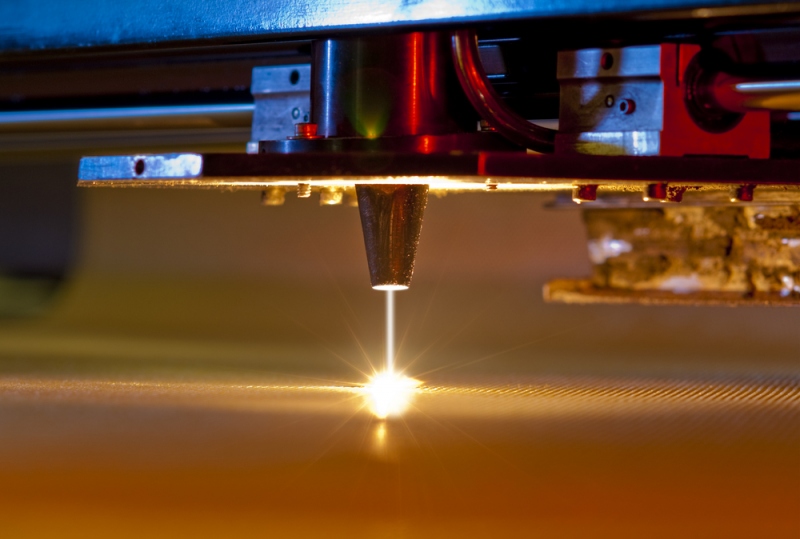

The core of the machine is the cabinet, realized in welded steel, which supports the 6-axis ABB anthropomorphic robot. On this robotic arm the laser scanning head, the camera and the distance measuring sensor are installed, in addition with the exhaust system. The triple supply shuttle (right-left-center) carries the parts inside the marking cabinet thank to an axis system activated by servomotors with racks. Each platform of the shuttle is covered with polyzene and there is no need of precise positioning because the parts are scanned and recognized by the vision system. An alarm will be generated in case of incongruity. The vision system is based on a camera in the center of the marking cabinet in order to focus on all the working area. It has to verify the congruity between the set code and the part on the charging plan while centering and finding the angulation referring to the predefined model. The control system needs these information in order to orientate the laser installed on the robotic arm.

The vision system for scanning the marking area is composed by a camera integrated on the marking head which defines a rectangle on the part (and/or other points) where the marking will be effectuated. Another Cognex camera reads and verifies the DataMatrix codes, while a laser telemeter measures the distance and the orientation of the marking plan in order to guarantee a perfect focusing.