Diesel engines are perfect for trucks and vehicles that are required to travel long distances, especially those moving heavy cargo. They last longer than gasoline engines and maintenance is generally low cost, though more frequent oil and filter changes are required to keep them running smoothly.

The urea injection system also needs to be refilled which is responsible for reducing nitrogen oxide emissions. This, along with regular oil and filter changes will keep your diesel vehicle going the distance without any hiccups.

A conventional gasoline-powered engine does not start aging prematurely if you get sloppy with the maintenance; however, the same approach towards a diesel engine can ruin it. This also applies to changing filters; a dirty one adversely affects your gas-powered vehicle, but when it comes to a diesel engine, you’re looking at a clogged fuel injection system, not to mention how much it might cost to get professional help to remedy the problems.

A good rule of thumb is to never take a DIY approach towards cleaning or making adjustments to the fuel injectors. Follow the instructions in the owner’s manual, and your diesel engine can easily crank out over a 100,000 miles. It’s no surprise truckers prefer diesels when it comes to the ‘long haul’ since they are tough and reliable, including low maintenance costs.

Diesels are generally designed to let the owner perform everyday maintenance drills without having to dish out too much cash or time. The first thing you should reach for when it comes to maintenance is your owner’s manual.

If, for some reason, replacement or maintenance process for a specific system or part isn’t mentioned in the manual, or you misplaced yours, simply contact your dealership and ask the Parts Department to provide a copy of the service manual. Some public libraries and even bookstores will have these available. If all else fails, you could Google it up.

Examine the manual’s sections carefully; perhaps some maintenance procedures can be done yourself. It is still highly recommended you take your diesel truck or vehicle to an authorized dealership for the very first checkup and maintenance/service. You might also ask them where the DIY maintenance parts are located and they should be happy to oblige.

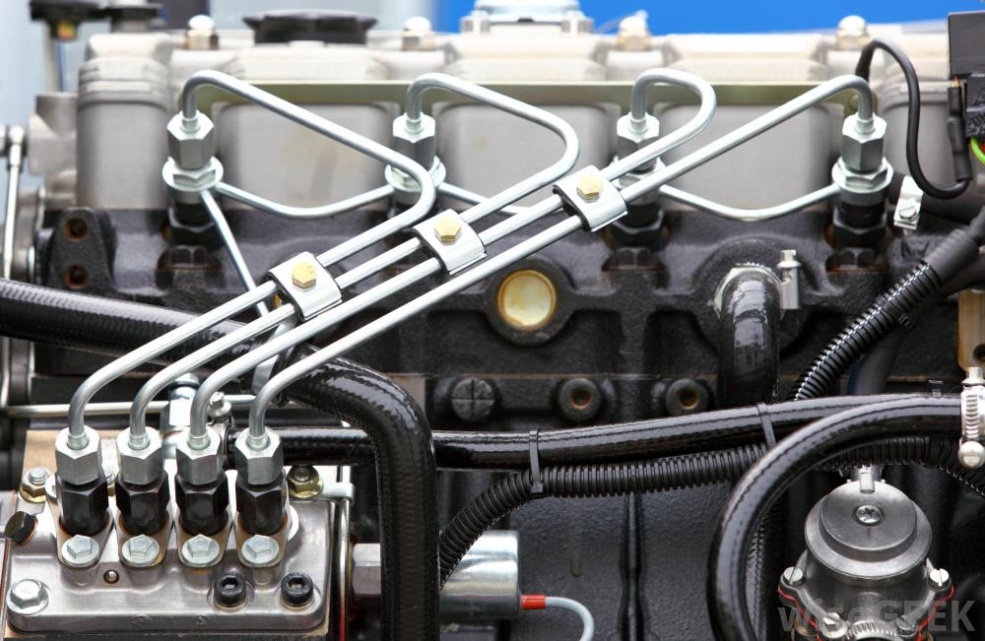

At a glance, some typical maintenance tasks associated with a diesel engine are:

- Changing lubricating oil

- Changing air filter

- Changing fuel filter

- “Bleeding” the fuel system, and;

- Draining the water separators

In addition, incorporate these tips to ensure your diesel engine runs smoothly throughout the year:

- Frequent oil and filter changes are important; refer to the owner’s manual for maintenance frequency though most truckers and diesel vehicle owners will tell you that every 3,000 to 5,000 miles is good, depending on usage.

- Oil filters replaced must, at the bare minimum, meet OEM filter manufacturer recommendations.

- When you’re at the pump for fuel, it’s always a good idea to add some diesel treatment. This will keep fuel impurities out of your engine.

- Idling for long periods must be avoided.

- Get the engine water separator drained. This part is responsible for filtering out water from the fuel. You can find it near the fuel filter. If your vehicle doesn’t come with one, you should have one installed as it can save money down the line on possible repairs.

- Gaskets need to be checked from time to time as they run under very hot conditions. If you come across a leaking gasket, you need to have the entire set replaced. If one’s going, the others are bound to follow.

Diesel engine maintenance is significantly less costly to maintain, compared to a regular engine. All you have to do is play your part and get the maintenance done as and when the schedule demands. Take all these tips into account to get the most performance out of your diesel vehicle, while improving longevity.

Apart from the engine, there are other diesel vehicle parts that need equal attention and regular maintenance. Find the right diesel truck tools to keep your heavy vehicle running smoothly.